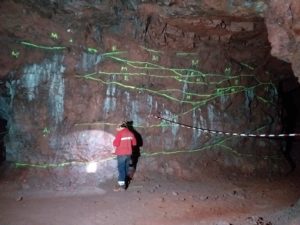

From the moment when the ore is extracted from the heart of our mine, Santa Rosa, to the time when it is put into the market as a pigment, it goes through several grinding phases to obtain our natural red pigments MICRONOX R01 and MICRONOX R02.

By reducing the size of the particle, the color of the iron oxide extracted from the mine changes from a bluish red with metallic undertone to the special yellowish red that distinguishes MICRONOX R01 and R02.

This transformation not only happens with natural iron oxides, but also with synthetic ones. This is why particle size control is a key factor in the consistency of the color of our pigments, and one of the reason for the strict quality control carried on by our technicians throughout the entire production process.